Coconut PanelBoard

Overview

COCONUT PANELBOARD

I undertook this project while completing my graduate program at Harvard. I wanted to explore product development opportunities for sustainable building systems using highly regenerative and renewable materials that impact producers and consumers. I researched the potential uses of coconut husks (coco coir) as a viable material for a new panelboard/fiberboard system.

The Philippines is second the largest coconut producer worldwide, and billions of coconut husks are discarded every year and turn into waste. Farmers harvest a coconut every 45 to 60 days, making it one of the most renewable and regenerative crops. The main product that comes from the coconut tree is coconut meat, which is processed into copra. Millions of coconut farmers depend on the copra industry (processed coconut meat for oil mills). The coconut husk is then discarded and frequently burned, which can turn into an environmental disaster.

I imagined that converting the coconut husk material into panel boards or fiberboards would be a potential application. Not only do we solve the environmental waste problem by utilizing the coconut coir wastes, but the material conversion will create tremendous livelihood opportunities for millions of marginalized farmers.

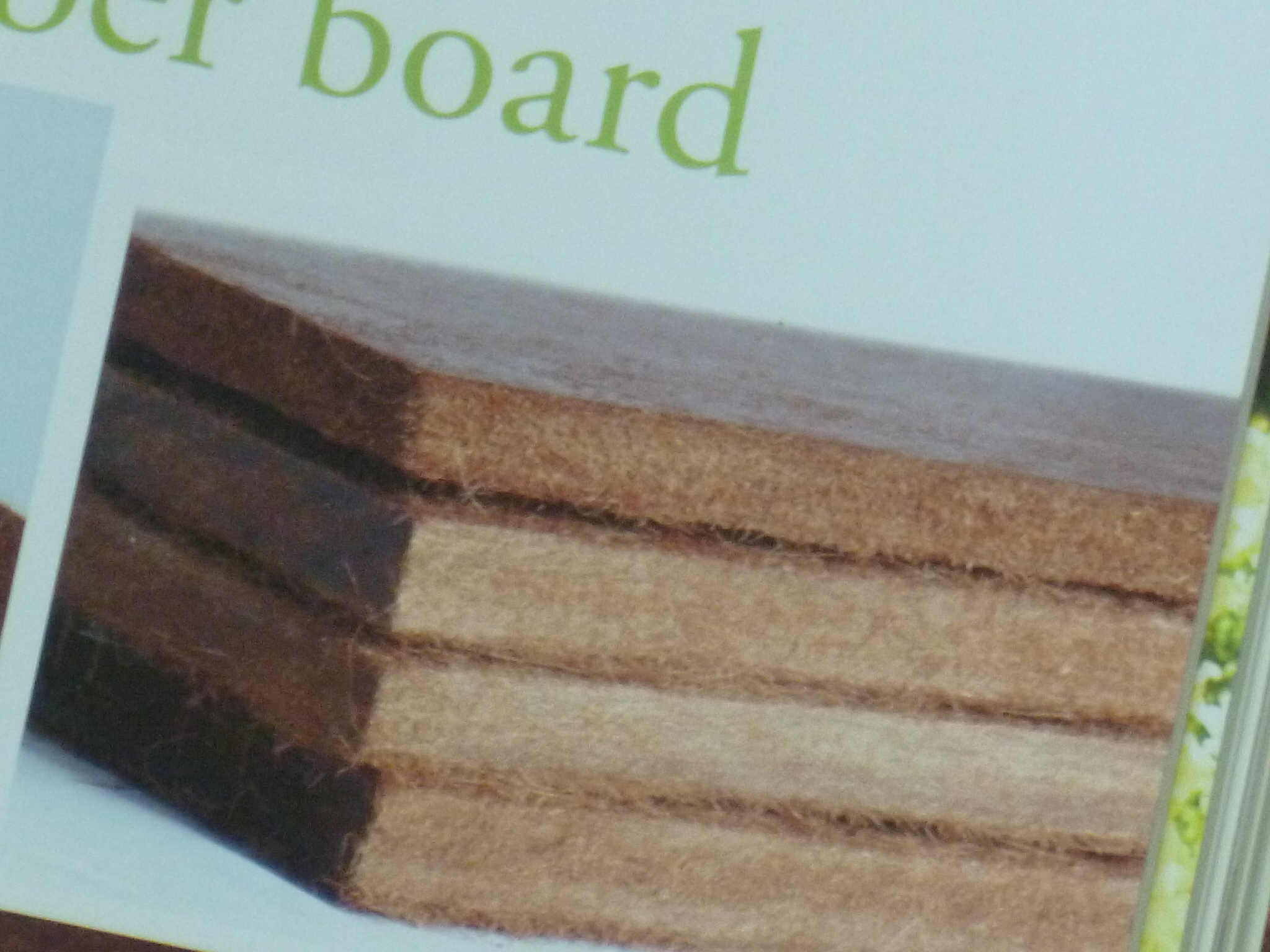

The fibers of the coconut coir are dense and relatively strong. If the final product can pass the rigid standards of building systems, this can provide one of the most ecological and highly renewable products. Every coconut panel board is a saved tree. Furthermore, if there will be a relatively low production cost, this will provide enormous savings and become a substantial component for affordable and low-income mass housing building systems.

During the first week of December 2005, I visited the University of Maine – Advanced Wood Engineering Center. Through the generosity and guidance of Prof. Stephen Shaler and Rusell Edgar, I learned the general process of panel board making, such as cement fiberboards, OSB, particle boards, medium density fiberboards, composite board, etc. I brought the coconut husk sample material. They were immediately placed into the cutting machine, which produced short fibers. As we examined the fibers, we then concluded that the coco coir material’s potential is for non-structural panelboard applications such as furniture, interior walls, and doors.

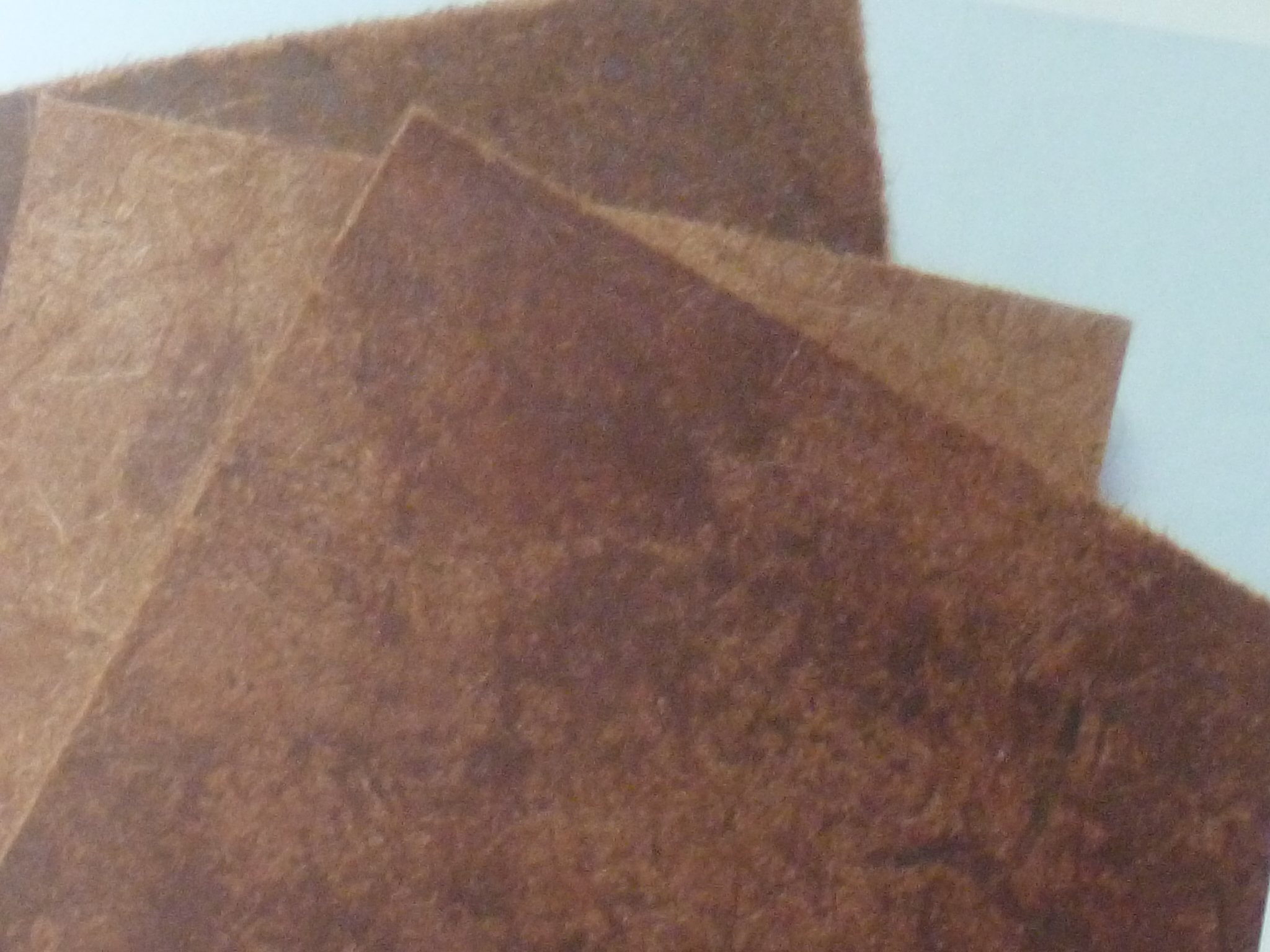

To fast track the study and prototype making, I traveled to Manila mid-December to get more literature on the topic. While in the Philippines, I manually produced a board prototype using the locally available regular water-based glue and formed the coco fiber into a small board. Because of the adhesive system used and the cold binding process, it took many days before the prototype hardened. In a very crude manner, I placed the board into a hot vulcanizing pressing machine to initially see the reaction of heat and pressure to the fiber material. The applied pressure and heat made the board tougher and denser. This process was an encouraging result as the fibers bonded quite well. I then visited the Philippine Coconut Authority, coconut farms, and several commercial converters/coco-coir material producers. The video and photo footages that I took documented the entire process of coco conversion from husk to coir fibers and the enormous coco husk wastes.

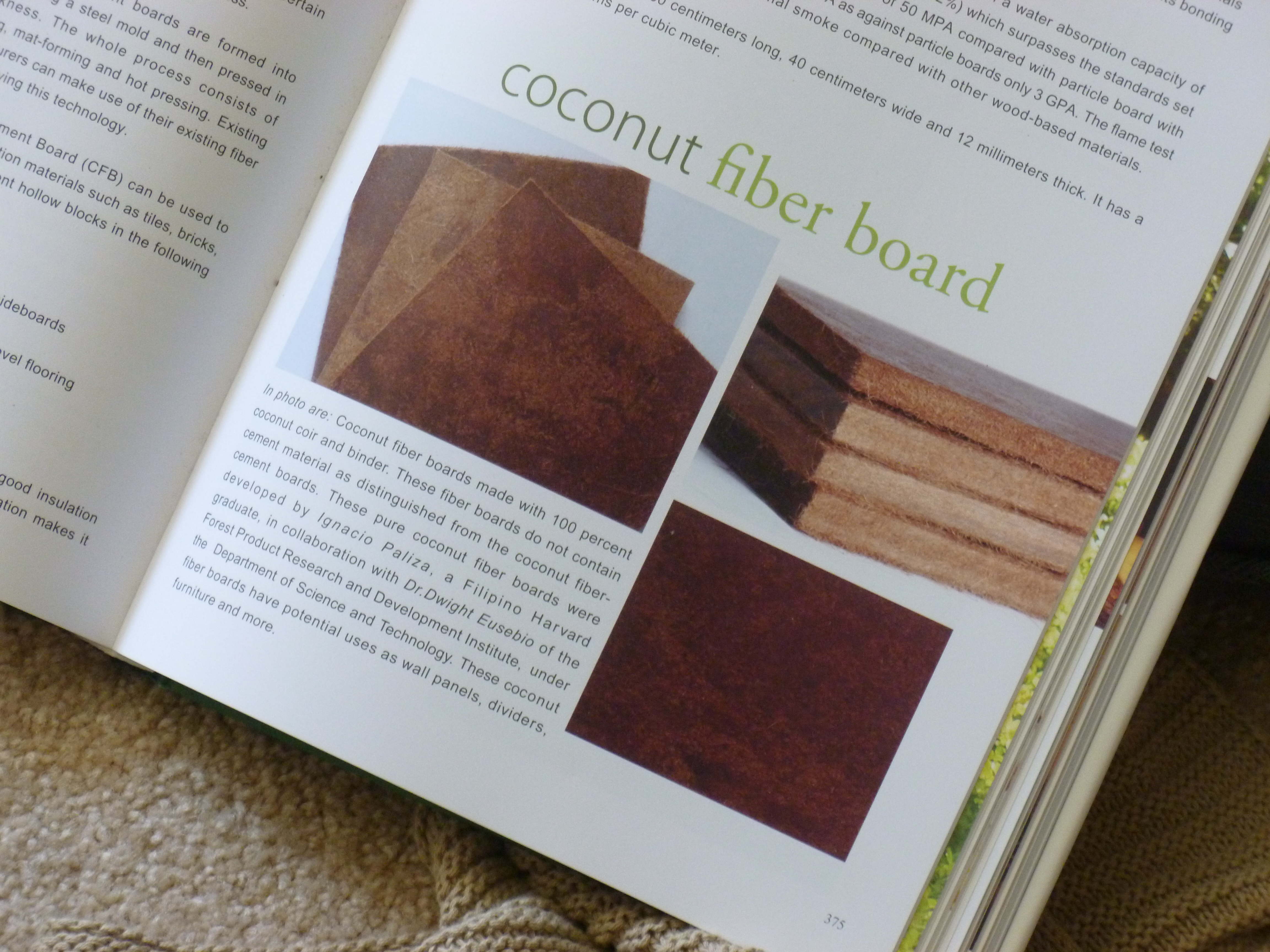

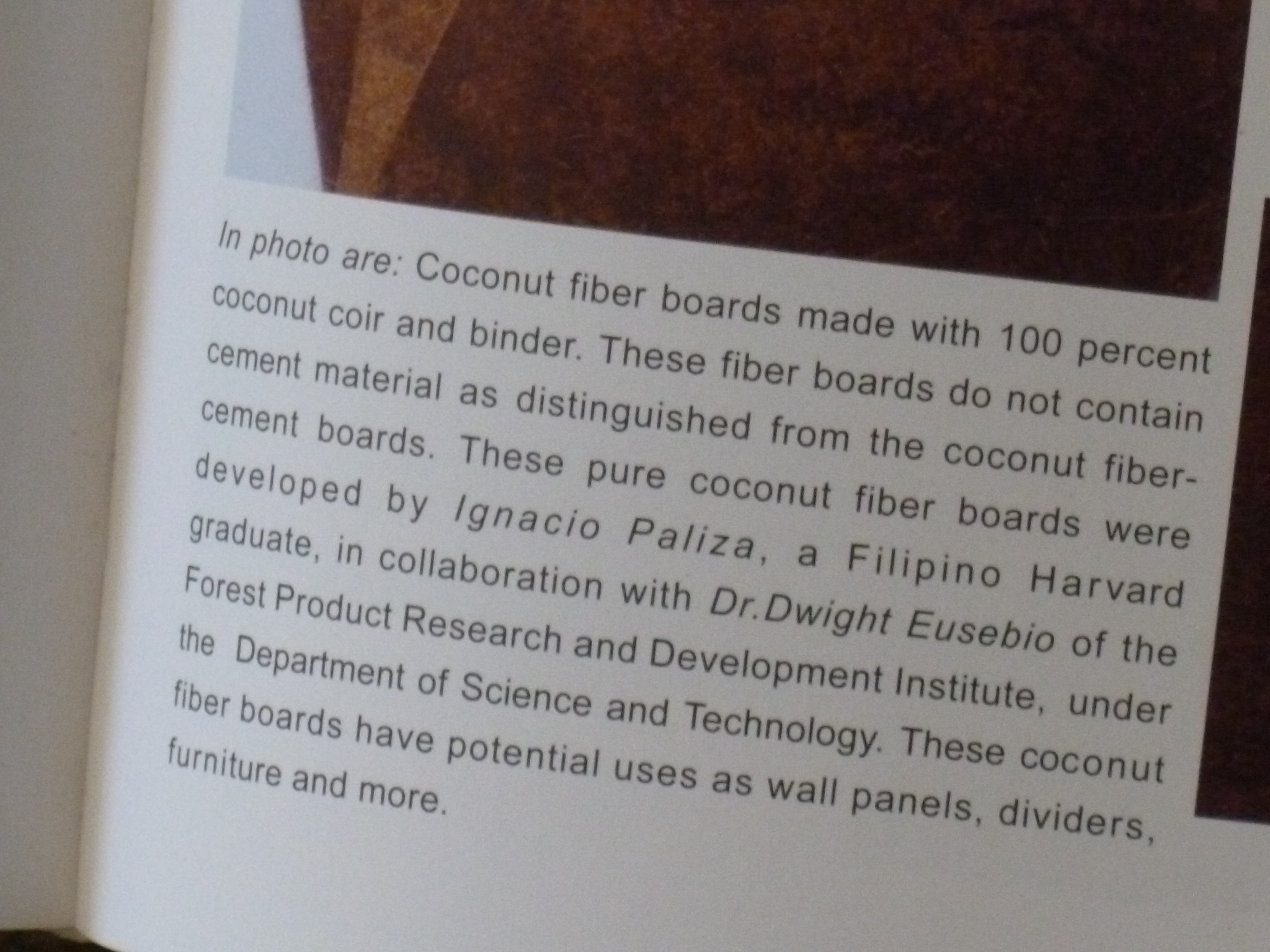

Finally, I visited the Forestry Department at the University of the Philippines, Los Banos. There, I learned of an old hot press machine that was not working. I immediately coordinated with the department to rehabilitate the equipment. In a couple of days, it was back to good working conditions, and in a week, we were able to use the hot press and produced the first coco fiber panelboard prototype. The challenge was to get the right mixture of composites and fibers. Initial runs indicated that the 5% mixture of binder resulted in a less bonded board than the board with a 10% mixture. Another combination was applying a fire retardant solution on the coco material before applying the composite mix. Further board property tests are required to validate the board strength, fire, termite, and fungi resistance. Hopefully, future studies will enhance the material properties of the coconut panelboard for non-structural panelboard applications.

COCO PANELBOARD MAKING PROCESS

Coco Coir Material Preparation

- De-husking of Coconut

- Coco Husk Material

- Collection

- First Phase Decorticating Process

- Second Phase Decorticating Process

- Screening of Coir Fiber

- Drying of Coir Fiber

- Compacting / Baling of Coir Fiber

Coco Fiber PanelBoard Production

- Computation of board composition – (i.e. density, thickness, size, material consumption, the proper ratio of chemical and additives)

- Weighing of Coir Fiber Material and other chemicals

- Trimming and Cutting to Size of Coir Fiber Materials

- Blending of Adhesive System – (i.e. Spraying of the adhesive system or blending through a machine)

- Forming of the Coco Fiber into a Form Box – Controlled amount of fibers are formed into a mat

- Hot Press – Pressing at high temperature while applying pressure to densify the mat, cure the resin, and remove excess moisture

- Trimming of Boards to specified sizes

- Sanding to reduce thickness variations and to improve surface appearance and strength.

- Inspection of board thickness and appearance.

Date